Description

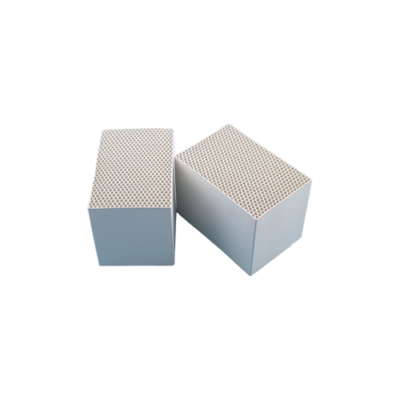

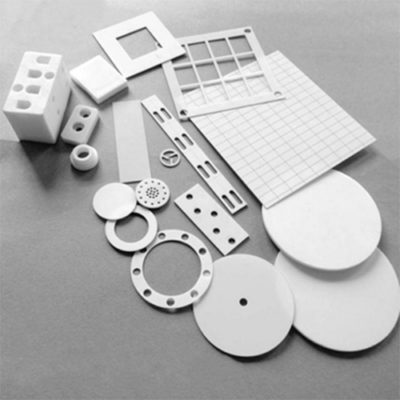

The zirconium sizing nozzle is crafted from stable zirconia and rare earth oxides through a process of high-pressure forming and high-temperature solid-phase treatment. Specific parameters and dimensions can be tailored to suit various user requirements and operational environments.

Distinctive Product Features: The inner core of the zirconium sizing nozzle boasts qualities of robust strength, excellent resistance to thermal vibration, corrosion, and erosion. It also exhibits a low expansion rate, ensuring an extended operational lifespan.

Application of the Product: The sizing nozzle serves as a functional apparatus made from high-temperature structural ceramics, designed for installation at the base of a continuous casting tundish. Its primary purpose is to maintain a consistent static pressure of molten steel within the tundish. As molten steel flows through the sizing nozzle into the mold, a substantial flow of water cools the mold, dissipating the heat released during the crystallization process. This causes the molten steel to solidify and transform into a billet. Given the limited heat extraction by water cooling, the quantity of molten steel entering the mold per unit time must be regulated within a specific range. The diameter of the sizing nozzle directly influences the molten steel flow rate into the mold. By selecting the appropriate aperture size, the tundish nozzle, or sizing nozzle, is created. This nozzle can also be employed for regulating the flow of other metal solutions.

| Component | Content |

|---|---|

| ZrO2 | ≥95% |

| Al2O3 | ≤0.2% |

| SiO2 | ≤0.4% |

| MgO | ≤2.9% |

| Fe2O3 | ≤0.1% |

| TiO2 | ≤0.1% |

| Density | 5.4 (g/cm3) |