Description

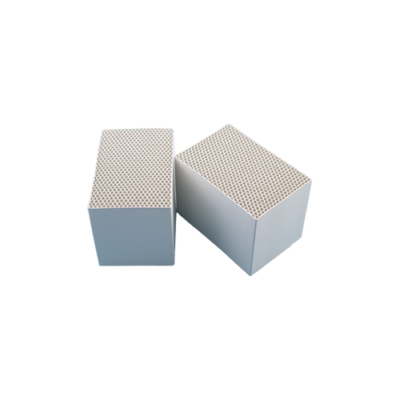

The stopper is a functional material made of refractory material, which is mainly used in the tundish. The use of the stopper can reduce the occurrence of incidents and improve the quality of the billet. An argon blowing hole can also be designed in the integral stopper to blow argon to the submerged nozzle to prevent the nozzle from being blocked.

The stopper has the advantages of good erosion resistance and erosion resistance, stable flow control during casting, tight closure after casting, etc.

Technique Data

Physical and chemical indicators:

| Item | Index | |

| SB45 | SB40 | |

| Al2O3 % | ≥45 | ≥40 |

| C % | ≥20 | ≥25 |

|

Flexural Strength MPa |

≥5.5 | ≥5.5 |

| Apparent porosity % | ≤19 | ≤19 |

| Bulk density g/cm3 | ≥2.36 | ≥2.2 |

Head Part:

| Item | Index | ||||||

| MC65 | MC60 | AC70 | AC65 | AC60 | MA70 | MA65 | |

| Al2O3 % | / | / | ≥70 | ≥65 | ≥60 | / | / |

| MgO % | ≥65 | ≥60 | // | / | / | / | / |

| Al2O3+MgO % | / | / | / | // | ≥70 | ≥65 | |

| C % | ≥9 | ≥12 | ≥9 | ≥12 | ≥15 | ≥8 | ≥10 |

| Bulk density g/cm3 | ≥2.45 | ≥2.4 | ≥2.65 | ≥2.6 | ≥2.55 | ≥2.6 | ≥2.45 |

| Apparent porosity % | ≤19 | ≤19 | ≤19 | ≤19 | ≤19 | ≤19 | ≤19 |