Description

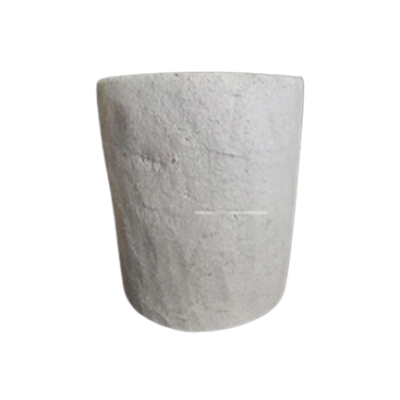

Magnesium Calcium Iron Dry Ramming Material is a dry compound composed of magnesium calcium iron sand and magnesia sand, meticulously graded for optimal composition. It finds its primary application in the construction of electric furnaces used for steelmaking and the production of ferroalloys.

Technique Data

| Item | Index | ||||

| MGT-1 | MGT-2 | MGT-3 | MGT-4 | ||

| MgO % | ≥78 | ≥81 | ≥82 | ≥85 | |

| CaO % | 12~15 | 6~9 | 8~11 | 6~8 | |

| Fe2O3 % | 4~5 | 5~9 | 3~5 | 4~5 | |

| SiO2 % | ≤1.3 | ≤1.5 | ≤1.1 | ≤1.3 | |

| Al2O3 % | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.6 | |

| Grain size composition mm | 0~6 | 0~6 | 0~6 | 0~6 | |

| Bonding Method | Ceramic Bonded | Ceramic Bonded | Ceramic Bonded | Ceramic Bonded | |

| Fired Cold Crush Strength MPa | 1300℃×3h | ≥10 | ≥10 | ≥8 | ≥10 |

| 1600℃×3h | ≥30 | ≥30 | ≥30 | ≥30 | |

| Permanent Linear Change% | 1300℃×3h | -0.2~-0.5 | -0.2~-0.5 | -0.2~-0.5 | -0.2~-0.5 |

| 1600℃×3h | -1.5~-2.5 | -2.0~-3.0 | -0.1~-0.2 | -1.5~-2.5 | |

| Particle bulk density,g/cm3 | ≥3.25 | ≥3.25 | ≥3.25 | ≥3.25 | |

| Usage | Electric steelmaking furnace | Electric steelmaking furnace | Electric steelmaking furnace | Ferroalloy electric furnace | |