Description

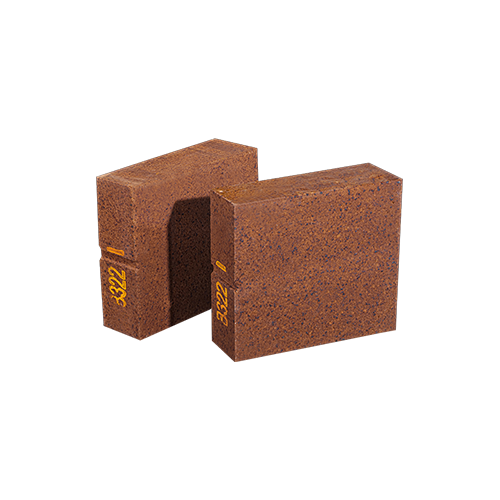

Magnesia iron spinel brick is a remarkable product designed for the “chrome-free” firing zone of cement kilns. It offers outstanding kiln skin adhesion, thermal shock stability, resistance to cement clinker erosion, and a low thermal expansion rate. Its application in the cement kiln firing zone yields excellent results.

Key Features of Magnesium Iron Spinel Refractory Brick:

- High compressive strength.

- Good thermal shock stability.

- Flexibility.

- High softening temperature under load.

- Easily adheres kiln skin.

Application Sites for Refractory Magnesium Iron Spinel Brick: Our Magnesium iron spinel refractory brick is suitable for various cement rotary kiln zones, including the firing zone, transition zone, and cooling zone. Choosing high-quality refractory materials, securing the kiln skin, and using appropriate fuels to slow down chemical erosion are pivotal factors in extending the rotary kiln’s service life. Our magnesia-iron spinel brick stands as your optimal choice for achieving these objectives.

| Item | Index | |

| Magnesia iron Spinel Brick | High toughness Magnesium Iron Spinel brick | |

| MgO % | ≥85 | ≥88 |

| Fe2O3 % | 5~7.5 | 5~6 |

| Al2O3 % | 3~5 | 4~7 |

| Bulk density g/cm3 | ≥3 | ≥2.9 |

| Apparent porosity % | ≤17 | ≤16 |

| Cold Crushing Strength MPa | ≥45 | ≥55 |

| Thermal shock resistance cycle 1100℃water cooling | ≥6 | ≥8 |

| 0.2MPa Refractoriness under load ℃ | ≥1600 | ≥1650 |

| Thermal expansion rate % 1400℃ | ≤1.6 | ≤1.7 |

| Thermal conductivity W/(m·K) 350±25℃ | ≤2.6 | ≤2.6 |