Description

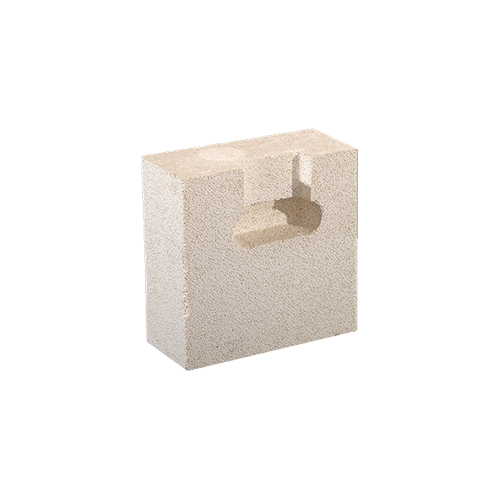

Mullite Insulation Brick stands as a high-quality refractory insulation material meticulously designed to endure and withstand elevated temperatures. It boasts attributes such as its lightweight nature, reduced thermal conductivity, exceptional heat insulation capacity, and heightened compressive strength, all well-suited for deployment within high-temperature furnaces or kilns. The primary applications of Mullite Insulation Bricks encompass the upper sections of hot blast stoves, the stacks, and bottoms of blast furnaces, regenerative chambers within glass melting furnaces, and the lining of ceramic high-temperature furnaces.

Key Characteristics of Mullite Insulation Brick:

- Notably low thermal conductivity and minimal heat capacity

- Demonstrates high purity and is marked by low impurity content

- Impressive strength even under high-temperature conditions

- Remarkable resistance to thermal shock

- Exemplary control over expansive conductivity

- Resilient against the erosive effects of both acids and alkalis

Mullite Insulation Brick encapsulates an intelligent synergy of properties that caters to the demanding requirements of heat-intensive industrial environments, rendering it an ideal solution for various critical applications.

| Item | Index | ||||

| JM23 | JM25 | JM26 | JM27 | ||

| Al2O3 % | ≥40 | ≥50 | ≥55 | ≥60 | |

| Fe2O3 % | ≤1.0 | ≤1.0 | ≤0.9 | ≤0.8 | |

| Apparent porosity % | ≤0.55 | ≤0.80 | ≤0.85 | ≤0.9 | |

| Cold Crush Strength MPa | ≥1.0 | ≥1.5 | ≥2.0 | ≥2.5 | |

| Permanent Linear Change Rate % | 1230℃×12h | 1350℃×12h | 1400℃×12h | 1450℃×12h | |

| -1.5~0.5 | |||||

| Thermal Conductivity W/(m·K) |

200±25℃ | ≤0.18 | ≤0.26 | ≤0.28 | ≤0.32 |

| 350±25℃ | ≤0.20 | ≤0.28 | ≤0.30 | ≤0.32 | |

| 600±25℃ | ≤0.22 | ≤0.30 | ≤0.33 | ≤0.36 | |

| 0.05MPa Refractoriness Under LoadT0.5 ℃ | ≥1080 | ≥1200 | ≥1250 | ≥1300 | |