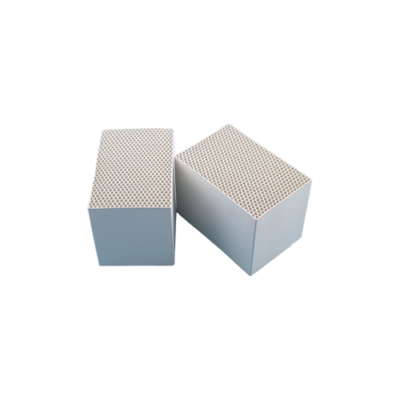

Description

The Ladle Shroud offers several advantages, including its versatile suitability for different steel grades, effective resistance to corrosion, robust thermal shock resistance, durability against molten steel scouring, and notable slag resistance. Furthermore, its user-friendly design contributes to improved operational efficiency and enhanced working conditions.

Key Features of the Ladle Shroud:

- Customizable argon injection structure based on customer specifications.

- Incorporates a ceramic glaze layer for effective prevention of material oxidation.

- Utilizes a ceramic fiber blanket to minimize heat loss during casting.

- Constructed from high-quality AL-C materials with exceptional corrosion and thermal shock resistance.

- Incorporates premium Zr-based composite materials to ensure high corrosion resistance at the slag line.

- Utilizes non-graphite based materials, meeting the demands for producing low carbon steel, silicon steel, and high purity steel.

Ladle Shrouds find applications in various contexts, including use in steel ladles, refining ladles, electric furnace refining ladles, and tundishes.

Technique Data

Physical and chemical indicators:

| Item | Index | ||

| CSK50 | CSK45 | CSK40 | |

| Al2O3 % | ≥50 | ≥45 | ≥40 |

| C % | ≥20 | ≥20 | ≥25 |

| Cold Crushing Strength MPa | ≥5.5 | ≥5.5 | ≥5.0 |

| Apparent porosity % | ≤19 | ≤19 | ≤19 |

| Bulk density g/cm3 | ≥2.2 | ≥2.18 | ≥2.16 |

Slag area:

| Item | Index | |||

| Z75 | Z70 | Z65 | Z55 | |

| ZrO2 % | ≥75 | ≥70 | ≥65 | ≥55 |

| C % | ≥9 | ≥12 | ≥15 | ≥18 |

| Apparent porosity % | ≤21 | ≤21 | ≤21 | ≤22 |

| Bulk density g/cm3 | ≥3.6 | ≥3.5 | ≥3.4 | ≥3.2 |