Description

Aluminum nitride (AlN) ceramic represents a novel ceramic material renowned for its exceptional comprehensive properties. It boasts a range of outstanding attributes, including remarkable thermal conductivity, reliable electrical insulation, low dielectric constant, and minimal dielectric loss. It is characterized by non-toxicity and thermal expansion compatibility with silicon, rendering it an ideal choice for cutting-edge applications like highly integrated semiconductor substrates and electronic device packaging. With a decomposition temperature reaching up to 2450℃ at room temperature, it serves as a versatile material for crucibles, evaporation boats, thermocouple protection tubes, and high-temperature insulating components used in the smelting of non-ferrous metals and semiconductor materials like gallium arsenide. Simultaneously, it finds utility as a high-temperature corrosion-resistant structural ceramic and transparent aluminum nitride ceramic.

Key Features:

- Exceptionally high thermal conductivity (up to 170W/m · K), comparable to BeO and SiC, exceeding Al2O3 by more than fivefold.

- Thermal expansion coefficient (4.5 × 10-6/℃) closely matching Si (3.5-4 × 10-6/℃) and GaAs (6 × 10-6/℃).

- Outstanding electrical properties encompassing dielectric constant, dielectric loss, volume resistivity, and dielectric strength.

- Strong mechanical attributes, exhibiting higher bending strength than Al2O3 and BeO ceramics, and amenable to sintering under normal pressure.

- Notable optical transmission characteristics.

- Effective insulation properties and resistance to plasma etching.

Applications:

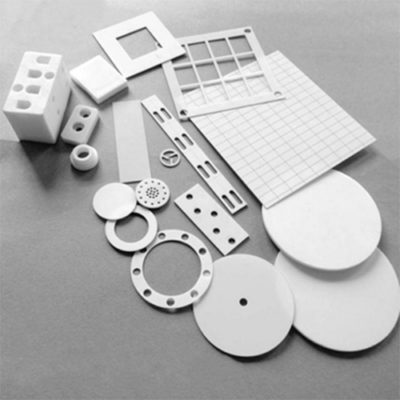

- Aluminum nitride ceramic substrates, featuring high thermal conductivity, low expansion coefficient, strength, high-temperature resilience, chemical resistance, resistivity, and low dielectric loss. These make it an optimal choice for heat dissipation substrates and packaging materials in large-scale integrated circuits.

- Aluminum nitride serves as a novel, high-hardness wear-resistant ceramic material, surpassing traditional aluminum oxide, suitable for parts subjected to severe wear.

- Leveraging AIN ceramics’ heat resistance, melt erosion resistance, and thermal shock resistance, it finds application in crafting GaAs crystal crucibles, Al evaporating dishes, magnetohydrodynamic power generation devices, corrosion-resistant parts for high-temperature turbines, and infrared windows due to its optical properties. AlN thin films are used for high-frequency piezoelectric components, VLSI substrates, and more.

- The heat-resistant, molten metal-corrosion-resistant, and acid-stable nature of aluminum nitride makes it ideal for smelting crucibles for metals like aluminum, copper, silver, lead, and for sintering and casting die materials. When exposed to humid air, a thin oxide film forms on the surface, enhancing its functionality.

Technique Data

| Item | Unit | Property Index | ||

| AN170 | AN200 | AN220 | ||

| Color | – | Gray | Gray | Beige |

| Water Absorption | % | 0 | 0 | 0 |

| Volume Density | g/cm3 | ≥3.3 | ≥3.3 | ≥3.26 |

| Surface Roughness | Um | 0.1-0.6 | 0.1-0.6 | 0.1-0.6 |

| Camber | Length‰ | ≤2 | ≤2 | ≤2 |

| Thermal Conductivity(20℃) | W/m.k | ≥170 | ≥200 | ≥220 |

| Coefficient of thermal expansion | 20℃~300℃(*10-6/℃) | 4.6 | 4.6 | 4.5 |

| 40℃~800℃(*10-6/℃) | 5.2 | 5.2 | 5.2 | |

| Bending Strength | Mpa | ≥450 | ≥300 | ≥200 |

| Modulus Strength | Gpa | 320 | 310 | 310 |

| Moh’s hardness | – | 8 | 8 | 8 |

| Dielectric Strength | KV/mm | ≥17 | ≥16 | ≥15 |

| Volume Resistivity | Ω.cm | ≥1014 | ≥1014 | ≥1013 |

| Dielectric constant | – | 9 | 8.6 | 8.5 |

| Dielectric Loss | X10-4 | 2.98 | 2 | 2 |