Description

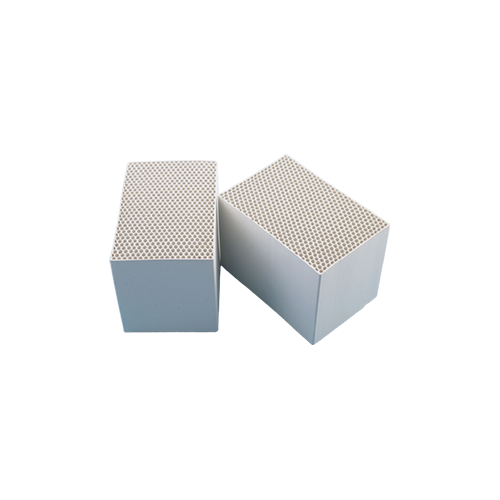

The SCR catalyst carrier is created through a high-temperature firing process, blending various raw materials to yield elevated overall activity and robust resistance to abrupt high temperatures. Its surface undergoes hardening treatment, conferring wear resistance and prolonged operational life. This compact yet expansive design boasts a substantial specific surface area and exceptional resistance to poisoning. The carrier excels in high denitration efficiency, demonstrating a low ammonia escape rate and SO2 conversion rate, while exhibiting commendable stability and durability.

Performance of the Catalyst Honeycomb Carrier:

- Versatility in applications, suitable for treating industrial organic waste gases encompassing carbon monoxide, hydrocarbons, and their oxygenated derivatives, as found in industries like petrochemicals, enameled wire production, coatings, and printing.

- Minimal gas flow resistance, low reaction initiation temperature, high activity, and a wide range of adaptable airspeeds. Effective purification is achieved within the concentration range of 2000-8000mg/m3 of hydrocarbon organic matter.

- Accommodates a reaction space velocity of 10000-30000h-1 and a reaction gas inlet temperature of 180-400°C, attaining a purification efficiency of ≥98%. It also exhibits commendable heat resistance, withstanding momentary exposure to temperatures up to 900°C.

- Boasts a prolonged operational lifespan, generally ranging from 1 to 3 years under normal operating conditions.

Application of the Catalyst Honeycomb Carrier: The catalyst honeycomb carrier finds relevance in treating waste gases laden with aromatics, oxygen, other organic substances, carbon monoxide, and other harmful poisons originating from industries such as chemicals, food, machinery, instrumentation, household appliances, paint spraying, insulating materials, and color steel manufacturing.

| Main Composition: | V2O5/WO3/TiO2 | Hole No: | 16~25 |

| Application Temp: | 300~420℃ | Denitration efficiency: | ≥90% |

| Ammonia escape Rate: | <3ppm | SO2 Conversion Rate: | <0.75% |

| Chemical life: | >24000h | Mechanical life: | >10年 |

| With uniform texture, high activity, high efficiency, low conversion rate and low activity attenuation, the denitration efficiency meets the industry requirements. | |||

Index

| Hole Quantity | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| Pitch/mm | 9.2 | 8.65 | 8.27 | 7.75 | 7.42 | 7.05 | 6.75 | 6.4 | 6.15 | 5.9 |

| Hole Dia/mm | 8.1 | 7.5 | 7.27 | 6.75 | 6.52 | 6.2 | 5.92 | 5.55 | 5.3 | 5.1 |

| Inner Dia/mm | 1.1 | 1.15 | 1 | 1 | 0.9 | 0.85 | 0.83 | 0.85 | 0.85 | 0.8 |

| Specific Surface Area m2/m3 | 368 | 385 | 418 | 433 | 463 | 486 | 509 | 521 | 542 | 566 |

| Opening rate/% | 74.65 | 72.25 | 76.11 | 73.10 | 75.57 | 75.34 | 75.39 | 72.42 | 71.91 | 72.25 |

(2)Cement industry catalyst

| Main Composition: | V2O5(MoO3)/TiO2 | Hole No: | 8~13 |

| Application Temp: | 180~300℃ | Denitration efficiency: | ≥90% |

| Ammonia escape Rate: | <5ppm | SO2 Conversion Rate: | <0.75% |

| Low volume, high activity, low decay rate; Resistance to sulfur and alkali metal poisoning | |||

Index

| Hole Quantity | 8 | 9 | 10 | 11 | 12 | 13 |

| Pitch/mm | 18.4 | 16.4 | 14.8 | 13.4 | 12.3 | 11.2 |

| Hole Dia/mm | 16.5 | 14.6 | 13.3 | 11.95 | 10.9 | 9.85 |

| Inner Dia/mm | 1.9 | 1.8 | 1.5 | 1.45 | 1.4 | 1.35 |

| Specific Surface Area m2/m3 | 187 | 210 | 236 | 257 | 279 | 295 |

| Opening rate/% | 77.44 | 76.74 | 78.62 | 76.80 | 76.04 | 72.87 |

(3)Catalyst for waste incineration power generation industry

| Main Composition: | V2O5(WO3)/TiO2 | Hole No: | 30~60 |

| Application Temp: | 160~300℃ | Denitration efficiency: | ≥90% |

| Ammonia escape Rate: | <3ppm | / | |

| Low temperature, sulfur resistance, water resistance and alkali metal pollution poisoning; High denitration efficiency | |||

Index

| Hole Quantity | 30 | 35 | 40 | 45 | 50 | 60 |

| Pitch/mm | 4.95 | 4.24 | 3.71 | 3.3 | 2.97 | 2.48 |

| Hole Dia/mm | 4.35 | 3.69 | 3.21 | 2.8 | 2.52 | 2.08 |

| Inner Dia/mm | 0.6 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 |

| Specific Surface Area m2/m3 | 696 | 803 | 913 | 1008 | 1120 | 1331 |

| Opening rate/% | 75.69 | 74.13 | 73.27 | 70.56 | 70.56 | 69.22 |

(4)Marine industry catalyst

| Main Composition: | V2O5(WO3)/TiO2 | Hole No: | 30~60 |

| Application Temp: | 250~550℃ | Denitration efficiency: | ≥90% |

| Ammonia escape Rate: | <10ppm | NO2 Conversion Rate: | ≥80 |

| Meet the operating conditions of low, medium and high-speed machines, with sulfur resistance, vibration resistance, high specific surface area and high denitration efficiency | |||

Index

| Hole Quantity | 30 | 35 | 40 | 45 | 50 | 60 |

| Pitch/mm | 4.95 | 4.24 | 3.71 | 3.3 | 2.97 | 2.48 |

| Hole Dia/mm | 4.35 | 3.69 | 3.21 | 2.8 | 2.52 | 2.08 |

| Inner Dia/mm | 0.6 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 |

| Specific Surface Area m2/m3 | 696 | 803 | 913 | 1008 | 1120 | 1331 |

| Opening rate/% | 75.69 | 74.13 | 73.27 | 70.56 | 70.56 | 69.22 |