Description

Beryllium oxide, a member of the cubic crystal system, exhibits a density of 3.03g/cm3 and a melting point of 2570℃. It showcases remarkable thermal properties, with a thermal conductivity (λ) ranging from 200 to 250W/(m·K), along with robust thermal shock resistance. Its dielectric constant stands at 6-7 (at 0.1MHz), while the dielectric loss tangent measures around 4 × 10-4 (at 0.1GHz). It proves highly resilient under conditions of vacuum up to 1800℃, inert atmospheres at 2000℃, and oxidative atmospheres at 1800℃.

Beryllium oxide ceramic, a cutting-edge ceramic material predominantly composed of beryllium oxide (BeO), is characterized by its exceptional attributes. These include elevated thermal conductivity, a high melting point, formidable strength, robust insulation, chemical and thermal stability, low dielectric constant, low dielectric loss, and excellent process adaptability. This advanced structural ceramic boasts outstanding performance and finds extensive utility in specialized fields such as special metallurgy, aerospace, vacuum electronics, nuclear technology, microelectronics, and optoelectronics. It is particularly prominent in applications involving high-power semiconductor devices, high-power integrated circuits, high-power microwave vacuum devices, and nuclear reactors. Over time, it has emerged as the predominant ceramic material for crafting components with high thermal conductivity.

Key Applications: Leveraging its exceptional thermal, electrical, nuclear, and mechanical properties, beryllium oxide ceramics find diverse applications. In the aerospace sector, they serve as carrier parts and assemblies. In the nuclear industry, they function as neutron retarders and radiation shielding materials for atomic reactors. Additionally, these ceramics excel as high-performance, high-power microwave packages, versatile high-power electric vacuum devices, and crucibles for melting rare and precious metals like uranium and plutonium. They also find utility as refractory materials for supporting rods in heating elements, showcasing their exceptional versatility across a wide spectrum of fields.

| Item | Test Condition | Unit | Index |

| Bulk Density | g/cm3 | ≥2.85 | |

| Beryllium oxide content | % | ≥99 | |

| Air tightness | Pass | ||

| Liquid permeability | Pass | ||

| Flexural strength | MPa | ≥170 | |

| Thermal shock resistance | Pass | ||

| Coefficient of linear expansion | 20℃-500℃ | ×10-6 /℃ | 7-8.5 |

| Thermal conductivity | 25℃ | W/(m·k) | ≥250 |

| Partial constant | 100℃ | W/(m·k) | ≥190 |

| Tangent value of dielectric loss angle | 1MHz 20℃ | 6.5-7.5 | |

| Volume resistivity | 10GHz 20℃ | 6.5-7.5 | |

| Breakdown strength | 1MHz 20℃ | ×10-4 | ≤4 |

| Chemical stability | 10GHz 20℃ | ×10-4 | ≤8 |

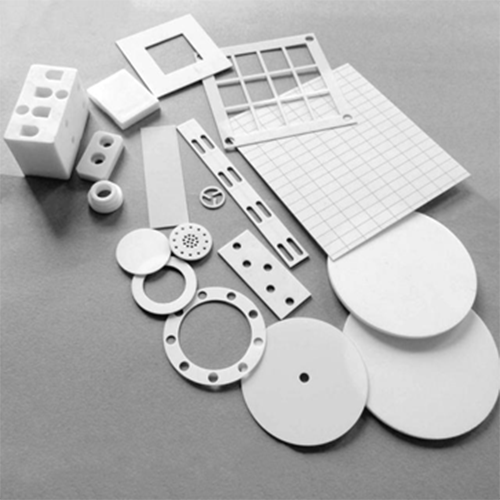

Main Products:

| N o | Product | Application |

| 1 | 99 Beryllium oxide ceramic substrate | Solid state electronics, various high-power devices, optical communication |

| 2 | 99 Beryllium oxide ceramic metallized substrate | Solid state electronics, various high-power devices, optical communication |

| 3 | 99 Beryllium oxide ceramic polishing substrate | Solid state electronics, various high-power devices, optical communication |

| 4 | 97 Beryllium oxide ceramic substrate | Solid state electronics, various high-power devices, optical communication |

| 5 | 99 Beryllium oxide ceramic pole | High power traveling wave tube |

| 6 | 99 Beryllium oxide ceramic tile | High power traveling wave tube |

| 7 | 99 Beryllium oxide ceramic column | High power electronic device |

| 8 | 99 Beryllium oxide ceramic cylinder | Vacuum device |

| 9 | 99 Beryllium oxide ceramic crucible | Melting |

| 10 | 99.5 Beryllium oxide ceramic shaped parts | Nuclear, high power period, vacuum device, microwave |