Description

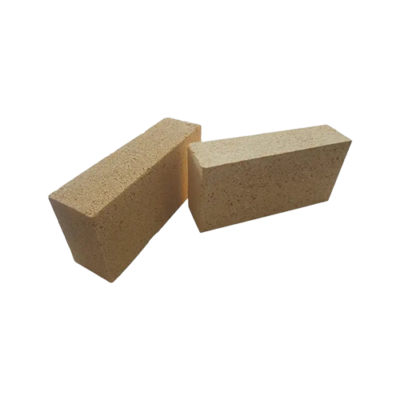

Clay-based Insulating Fire Bricks represent a refractory material engineered for high-temperature insulation. This composition is crafted from refractory clay clinker as the foundational ingredient, bound together with plasticized clay acting as a binder. To enhance properties, a precise amount of combustible additives or foaming agents is introduced. These bricks find extensive application as inner lining components within industrial kiln walls and furnace structures.

Characteristics of Clay Insulating Fire Bricks:

- Elevated Refractoriness, with an incapacity to directly engage flames

- Considerable Porosity

- Reduced Thermal Conductivity

- Diminished Bulk Density

- Impressive Resistance to Thermal Shocks

- Exceptional Heat Insulation Capabilities, promoting energy efficiency

- Resilience to Corrosion and Erosion

- Prolonged Service Life

Diverse Applications of Clay Insulating Fire Bricks: Clay insulating fire bricks possess a versatile scope of utility. They are prominently employed in various contexts, such as thermal boilers, glass kilns, cement kilns, fertilizer gasifiers, blast furnaces, hot blast stoves, coking furnaces, electric furnaces, and the production of steel casting and pouring bricks.

Furthermore, these bricks serve as crucial components for thermal surface refractories or as complementary materials for insulation in an array of scenarios. Examples encompass melting furnaces, ignition kilns, flues, refining equipment, heating devices, regenerators, gas furnaces and conduits, soaking furnaces, annealing furnaces, reaction chambers, and other industrial thermal apparatuses.

| Item | Index | ||||||

| NG1.5 | NG1.3 | NG1.2 | NG1.0 | NG0.8 | NG0.6 | NG0.5 | |

| Bulk Density g/cm3 | ≤1.5 | ≤1.3 | ≤1.2 | ≤1.0 | ≤0.8 | ≤0.6 | ≤0.5 |

| Cold Crush Strength,MPa | ≥6 | ≥5 | ≥4.5 | ≥3.5 | ≥2.5 | ≥1.3 | ≥1.0 |

| Permanent Linear Change Rate % | -2~1 | ||||||

| 1400℃×12h | 1350℃×12h | 1300℃×12h | 1250℃×12h | 1200℃×12h | 1150℃×12h | ||

| Thermal Conductivity W/(m·K) 350±25℃ |

≤0.65 | ≤0.55 | ≤0.50 | ≤0.40 | ≤0.35 | ≤0.25 | ≤0.23 |